Friday Facts 10: How to assemble 109:1 harmonic gearbox

This is the harmonic gearbox we sell as individuals or in a 6-pack to make the Sixi 3 robot arm. At ten minutes each, you can have your entire arm assembled and ready in under 2 hours.

This is the harmonic gearbox we sell as individuals or in a 6-pack to make the Sixi 3 robot arm. At ten minutes each, you can have your entire arm assembled and ready in under 2 hours.

The Sixi Calibration Tool helps anyone using a Sixi robot make sure that the robot’s mental and physical states match.

If they do not match then the move you expect is not the move you will get. This could very quickly lead to an accident.

There has to be a way to synchronize the mental model and the physical model. The calibration tool is made to fit in one place and attach to the arm in only one way. This forces all the robot joints to move to known angles. Those angles are measured in the mental model in Robot Overlord and then copied to the physical model in the robot’s brain.

| Joint | Angle (degrees) |

| 0 (x) | 0.0 |

| 1 (y) | -41.3 |

| 2 (z) | 74.5 |

| 3 (u) | 0.0 |

| 4 (v) | -33.5 |

| 5 (w) | 0.0 |

A good designer and leader knows when to say “no”. In today’s example… I have tried several times with the help of Instagram friends and my own employees to build a gripper that we can use with the Sixi robot. I decided, finally, to say No. We’re in the robot arm business, not the gripper business. If that’s true then how will Sixi hold grippers made by other people?

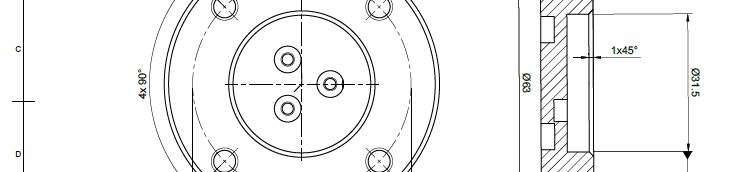

“ISO 9409-1:2004 defines the main dimensions, designation and marking for a circular plate as mechanical interface. It is intended to ensure the exchangeability and to keep the orientation of hand-mounted end effectors.”

https://www.iso.org/standard/36578.html

Are you looking for a challenge? How about making a gripper that works with our STL model of the hand? Then it should work with all commercial robot arms that match the standard, too.

Here’s a link to the DIN EN ISO 9409-1-50-4-M6 STL file.

The Sixi robot arm can reach 80cm (31.5in) and carry 2kg (4.4lbs). That’s a lot of power and versatility! In the wrong hands it could be trouble. Here’s a list of things that you should NEVER do with a Sixi robot arm.

Some ideas we have tested under very strict safety guidelines to show you why they’re a bad idea.

Some ideas we read about… then we folded the paper and put it in a fire.

Look, I get it, secret agents are getting all up in your base. Please! Resist the urge. Your Sixi will get PTSD. Also, the Secret Agent union is really mean.

It’s all good clean fun until it isn’t, and then you can count only to 512. Segue: I want to point out the Bishop pulled an Andy Dufresne – before it was cool – and saved the remaining humans from that space hell. That should go on the DO list.

While we are all in favor of villainy, the human imagination is nearly limitless. Please don’t stab, slice, burn, scar, tattoo, shave, tenderize, cook, melt, or do other unpleasant things with humans, pets, or other living things. If you’re not sure what this means, draw a picture of what you want to do and show it to your parents or a lawyer. Do they approve? Cool.

Remember: all accidents can be traced back to at least three mistakes. A little paranoia is totally acceptable here, it’s okay to let it off leash here.

If you’re still not sure if your task is safe (or how to do it safely), ask in our forums.

After people ask “what good is a robot arm like Sixi?” the next question is always “how strong is it and how far can it reach?” To answer the reach question visually, I wanted to calculate the boundaries of the Sixi robot’s workspace.

Here’s a paper I found about an analytical method that starts with the Jacobian of a robot and goes from there: https://pdfs.semanticscholar.org/e5f8/d98ce96b1dfcce05966bed52a85a215cf0a9.pdf

Here’s another locked behind a paywall: https://www.semanticscholar.org/paper/Calculation-of-the-Boundaries-and-Barriers-of-the-a-Peidro-Reinoso/58ebab14786596a892eccf07f9a8750d40fa0a78

Looking closer at the abstract for each paper I find, there doesn’t seem to be a consensus on the best way to find the workspace boundary. Some even call for Monte Carlo methods (eg some fuzzy guesswork). A large part of the problem seems to be that the boundary is a concave hull, possibly even with unreachable interior pockets (like a donut hole). These are much harder to compute than a convex hull.

I have Robot Overlord and its IK/FK solutions. I could move the arm through the entire workspace on the planes I care about and plot points in a giant table of data, then feed that to something like MATLAB and ask it to generate the best-fitting outer perimeter. MATLAB has a boundary() method that should work pretty good.

While waiting for MATLAB to install, I generated the XZ and XY plots.

For the XY plot I made the arm stretch out as far as possible, turned it around the base, then reach in as close as possible and turn the other way. That meant turning the anchor, the shoulder, and the elbow. This was all done with Forward Kinematics, which can easily calculate the position of the robot’s hand. I swept through the range, moving 1 degree at a time, and dumped the hand positions into a CSV file, which I then graphed in OpenOffice Calc. The result looks like a Pacman.

For the XZ workspace plot I repeated the process by turning the shoulder, the elbow, and the wrist.

MATLAB was crazy slow and not needed for the plot I wanted. I guess it would be good if I was drawing a 3D envelope? But I’m not, so it’s overkill.

You can find the code to generate the plots in https://github.com/MarginallyClever/Robot-Overlord-App/blob/master/src/test/java/com/marginallyclever/robotOverlord/MiscTests.java. There is a plotXZ() and a plotXY() that generate the CSV files needed for each graph.