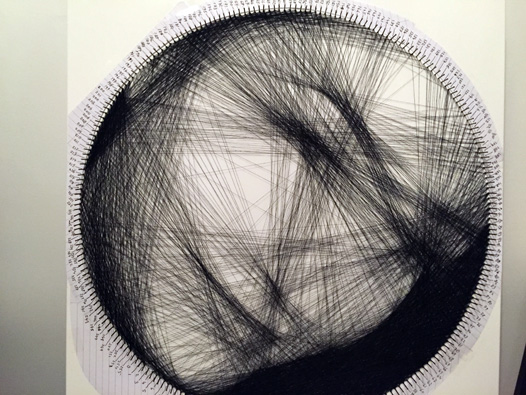

Circular Weaving IRL

Github user Neyestan posted to the circular weaving project his recent results making a weaving pattern In Real Life. Check it:

(more…)

Github user Neyestan posted to the circular weaving project his recent results making a weaving pattern In Real Life. Check it:

(more…)This video shows Multi-material 3D printed Soft Robots, which is a lot of fun stuff in one package. Researchers from the Wyss Institute at Harvard University developed a really fast way to switch materials while 3D printing and then used it to print robots that were a combination of soft and rigid parts.

Fantastic! I would love to see this used for easily dissolved support material, or circuits embedded into the bones of my robots.

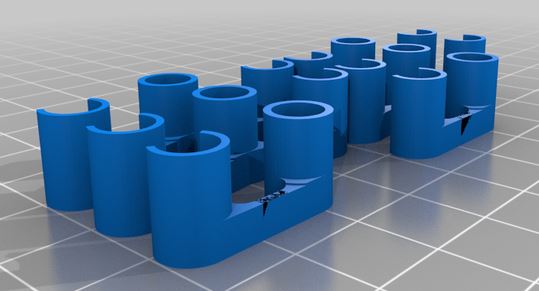

The tensioner is a new idea to reach higher speeds by making sure the belts can never skip off the pulleys. It uses a rollerskate bearing – you’ve seen them in fidget spinners – and is 3D printed. Jason Garber remixed and improved the design, which delights me to no end.

He said the middle pieces (2mm bend) is the his favorite. Here it is in action on Jason’s machine:

This morning I was flooded with like and subscribe emails on my hackaday page for the Sixi. Turns out someone had written about it in a tech site and not given me the heads up. Nobody tells me nothing .

Do me a favour and go upvote the project on hackaday. I’d love to win their contest and get some toys to further development. Your continued support can make that happen. Thanks!

It was never going to be strong enough as a robot arm, so they turned it around and made it into an interface device. The amount of room needed for the linkages to move around is not practical.

On the plus side, it’s got a lot of the hardware that robots use and may serve as a great education for people starting out in the field: encoders, position sensors, DC brushless motors, control, and more.