Shift registers and seven segment displays in Arduino

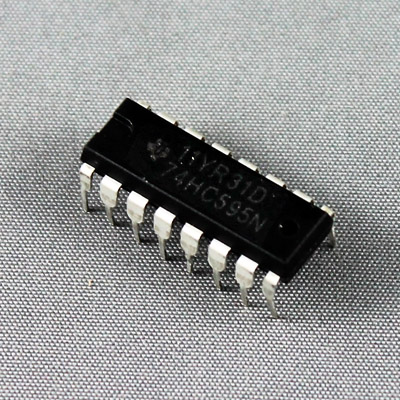

In previous tutorials I showed how to use seven segment displays, how to use shift registers and how to daisy chain shift registers, and talked a bit about persistence of vision. In this tutorial we’re going to combine shift registers and seven segment displays to make an Arduino control two four-character seven-segment displays, a task that (at first glance) might not seem possible.